elfcam

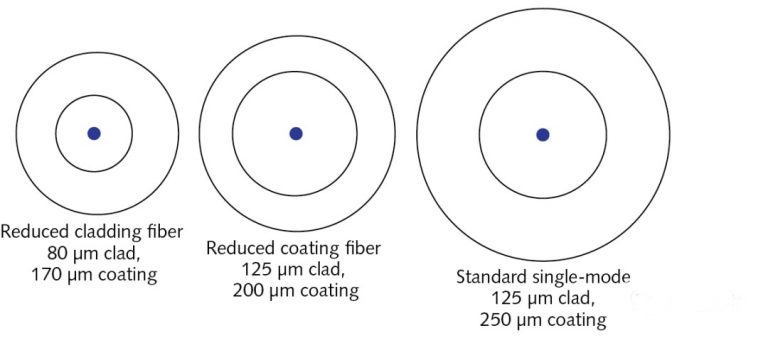

Fiber optic specialist

- All products

- Optical Cable

-

-

- Simplex to Simplex Optical Patch Cord

- SC/APC-SC/APC (Orange,SFR,Bouygues) White€5,87 incl. tax

- SC/APC-SC/APC (Orange,SFR,Bouygues) Yellow€6,36 incl. tax

- SC/APC-SC/UPC (Free) White€5,38 incl. tax

- SC/APC-SC/UPC (Free) Yellow€6,85 incl. tax

- LC/APC-LC/APC White

- LC/APC-LC/APC Yellow€8,81 incl. tax

- LC/APC-SC/APC White

- LC/APC-SC/APC Yellow€6,74 incl. tax

- LC/APC-LC/UPC White

- LC/UPC-SC/APC Yellow€7,34 incl. tax

- LC/UPC-SC/APC White

- LC/UPC-LC/UPC Yellow€5,99 incl. tax

- SC/UPC-SC/UPC White€6,66 incl. tax

- SC/UPC-SC/UPC Yellow

- E2000-LC/APC

- FC/PC-FC/APC7,83 € incl taxes

- FC/PC-FC/PC€8,81 incl. tax

- FC/PC-SC/APC€8,81 incl. tax

- SC/UPC-SC/UPC 5,0mm Black

- LC/APC-LC/APC 5,0mm Black

- Simplex to Simplex Optical Patch Cord

-

-

-

- Duplex Optical Patch Cord

- OM3 LC/UPC LC/UPC€8,81 incl. tax

- OM4 LC/UPC LC/UPC€8,81 incl. tax

- OS2 Duplex LC/APC LC/APC€7,83 incl. tax

- OS2 Duplex E2000/APC LC/APC

- OS2 Duplex LC/APC LC/UPC

- OS2 Duplex LC/UPC LC/UPC€8,81 incl. tax

- OS2 Duplex SC/APC SC/APC8,81 € incl taxes

- OS2 Duplex SC/APC LC/UPC€8,62 incl. tax

- OS2 Duplex SC/UPC LC/UPC€9,79 incl. tax

- OS2 Duplex FC/PC FC/APC€9,79 incl. tax

- OS2 Duplex FC/PC FC/PC€9,79 incl. tax

- OS2 Duplex FC/PC SC/APC€9,79 incl. tax

- OS2 Duplex ST/UPC LC/UPC

- OS2 Duplex ST/UPC ST/UPC

- OM3 ST/UPC LC/UPC

- OM3 ST/UPC ST/UPC

- OM3 LC/UPC SC/UPC

- OM3 SC/UPC SC/UPC

- MPO 12Fibers39,81 € incl taxes

- MPO 8Fibers

- MPO 8Fibres Breakout

- Duplex Optical Patch Cord

-

-

-

- Outdoor Optical Cable

-

-

- Fiber Optic Cable with Armor

- Simplex SC/APC SC/APC in armored steel€10,99 incl. tax

- Simplex SC/APC SC/UPC in armored steel€12,69 incl. tax

- Simplex LC/APC SC/APC in armored steel

- Simplex LC/APC LC/APC in armored steel

- OS2 Duplex LC/UPC LC/UPC in armored steel

- OM3 Duplex LC/UPC LC/UPC in armored steel€39,99 incl. tax

- OM3 Duplex LC/UPC Armored Steel LC/UPC Black

- OM3 Duplex SC/UPC SC/UPC Black

- Fiber Optic Cable with Armor

-

- Fiber Optic Cable outside

- Fiber Optic Cable SC/APC - SC/APC (all operators)€56,99 incl. tax

- Outdoor Fiber Optic Cable 1-2-4 fibers

- Fiber Optic Cable (Indoor for work) 1-2-4 fibers

- OS2 Simplex SC/UPC-SC/UPC Outdoor Fiber Optic Cable

- OS2 Duplex Fiber Optic Cable LC/UPC-LC/UPC Outdoor

- OS2 Simplex LC/APC LC/APC Outdoor Fiber Optic Cable

- OM3 Duplex Fiber Optic Cable LC/UPC-LC/UPC Outdoor

- Fiber Optic Cable outside

-

-

- Optical Module

-

-

- Optical Module

- SFP SC Simplex TX1310

- SFP SC Simplex RX1310

- SFP SC Simplex Lot2 (TX1310-RX1310)

- SFP LC Simplex TX1310

- SFP LC Simplex RX1310

- SFP LC Simplex Lot2 (TX1310-RX1310)

- SFP LC Duplex Lot2 (OS2)

- SFP LC Duplex Lot2 (OM3/OM4)

- 10GSFP+ LC Duplex (OM3/OM4)

- 10GSFP+ LC Duplex (OM3/OM4) Lot 2

- 10GSFP+ LC Simplex 20km

- 10GSFP+ LC Duplex (OS2)

- 10GSFP+ LC Duplex (OS2) Batch 2

- SFP RJ45 (1,25G)

- 10GSFP+ RJ45

- 10G Direct Attach Cable (DAC)

- 25G Direct Attach Cable (DAC)

- 10G Direct Attached (AOC) Fiber

- 25G Direct Attached (AOC) Fiber

- Optical Module

-

-

-

-

-

- Optical Adaptation

-

-

- Adapter

- SC-SC APC Single Mode Adapter

- SC-SC UPC Single Mode Adapter

- LC/UPC-LC/UPC Single-mode duplex adapter

- LC/UPC-LC/UPC Multimode duplex adapter

- LC-LC APC Female-Female Single Mode Simplex Adapter

- LC-LC APC Single Mode Duplex Adapter

- LC-LC UPC Female-Female Single Mode Adapter

- SC-LC UPC Male-Female Single Mode Simplex Adapter

- SC-LC APC Male-Female Single Mode Simplex Adapter

- FC-LC UPC Male-Female Single Mode Adapter

- Simplex Single Mode FC-FC Adapter

- SC/APC-SC/APC Single Mode Duplex Adapter

- SC/APC-LC/APC Female-Female Single Mode Simplex Adapter

- SC/APC-LC/APC Female-Male Single Mode Simplex Adapter

- LC/UPC Optical Fiber Rapid Connector

- SC/APC Fiber Optic Rapid Connector

- Adapter

-

-

-

- pigtail

- Fiber Optic Pigtail 12 Fibers SC/APC Color

- Fiber Optic Pigtail 12 Fibers SC/UPC Color

- Fiber Optic Pigtail 12 Fibers LC/UPC Color

- Fiber Optic Pigtail 12 Fibers SC/APC White

- Fiber Optic Pigtail 12 Fibers SC/APC Yellow

- Fiber Optic Pigtail 12 Fibers LC/APC White

- Fiber Optic Pigtail 12 Fibers LC/APC Yellow

- Fiber Optic Pigtail 24 Fibers SC/APC White

- Fiber Optic Pigtail 48 Fibers SC/APC White

- Fiber Optic Pigtail (12 FO) OM3 LC/UPC

- Fiber Optic Pigtail (12 FO) OM4 LC/UPC

- pigtail

-

- Optical Network

- Optical Tool

-

-

- Tools

- ELFCAM K1 High Precision Cleaver

- ELFCAM SE High Precision Cleaver

- SE-09 Cleaver 48,000 Cuts

- Smoove Transparent for Optical Fiber Soldering€37,80 incl. tax / 1000 pieces

- Supvan LP5120M labeler

- Kevlar Scissors for Optical Fiber

- Kevlar Scissors for Optical Fiber Blue

- Fiber Optic Stripping Pliers

- Coaxial Coax Cable Stripping Pliers

- Kevlar Scissors for Optical Fiber + Ergonomic Stripping

- Tools

-

- Ethernet cable

- Optical Cable

- Solutions

- Information

- About us

Professional

elfcam

A4, 32 Avenue de l'épi d'or, 94800, Villejuif, France

Kolner Str.366, 40227 Dusseldorf, Deutschland